-

-

Make sure that cases aren't loaded upside down and that they're facing the right way when entering the former.

-

-

-

If the cases are torn or bent, they may not form properly.

-

Remove any case blanks that have visible damage.

-

Make sure that the score lines in the cases are as well defined. Your corrugate supplier can help with this by making sure that correct scoring pressure is used for your case specification.

-

-

-

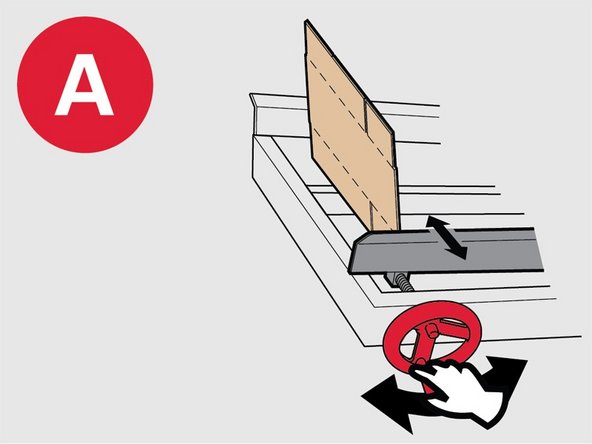

Check to make sure that the case blank tray guides are correctly adjusted.

-

Guides are adjusted using the Dimension A hand wheel.

-

The guides shouldn't be too tight or too loose. Apply just enough pressure to support the case blank sides and allow them to rest freely at the end of the tray.

-

-

-

Check to make sure that the bottom flap guide is correctly adjusted.

-

Use the scale on the outer frame to measure the bottom minor flap.

-

Turn the Dimension M hand wheel to the measured height of the bottom flap.

-

Almost done!

Finish Line