Introduction

The process of loading the hopper is a simple one, but following these tips will prevent tray jams and increase machine up-time.

-

-

Before loading, make sure that you can identify the interior side of the tray, as well as the leading and trailing edges of the tray.

-

Make sure that the leading edge of the blanks are pointing in the correct direction and the interior side is facing up.

-

-

-

If the trays are torn or bent, they may not form properly.

-

Remove any blanks that have visible damage.

-

-

-

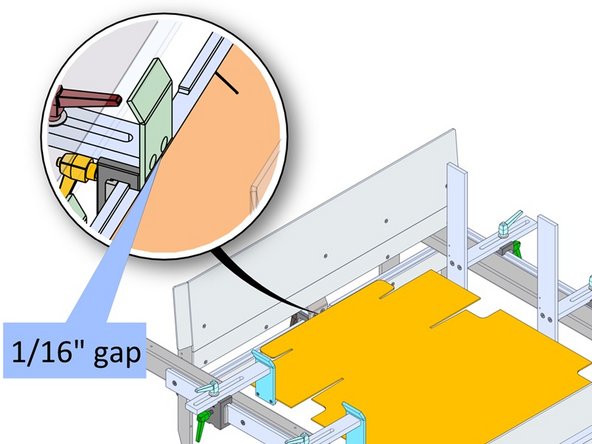

If tray blanks are falling through the hopper or getting jammed in the hopper, the hopper guides need adjustment.

-

Place a tray blank in the hopper and adjust each guide so that there is a 1/16" gap between the tray edge and the hopper guide.

-

-

-

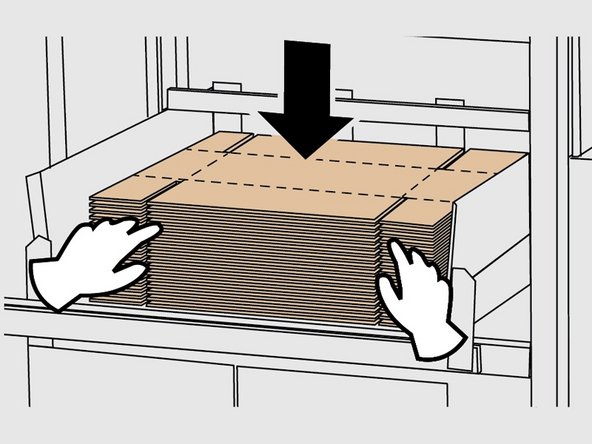

When the amount of tray blanks in the hopper reaches the “low” state, the tray former continues to run but a Low Hopper warning message appears on the HMI. You can refill the hopper without stopping the tray former.

-

Place a stack of blanks on top of the ones currently in the hopper. Make sure that the new blanks sit within the hopper guides, and are in the correct orientation.

-

The tray former continues to run and the HMI removes the Low Hopper warning.

-

Thank you for contacting us. For us to better assist you, please reach out to our technical support by phone at 1.888.565.3219 or 604.930.9300 or by email at Wexxar.Service@promachbuilt.com or Wexxar.Parts@promachbuilt.com along with your machine model and serial number. One of our tech support reps will be glad to answer any questions you may have.

Thank you for contacting us. For us to better assist you, please reach out to our technical support by phone at 1.888.565.3219 or 604.930.9300 or by email at Wexxar.Service@promachbuilt.com or Wexxar.Parts@promachbuilt.com along with your machine model and serial number. One of our tech support reps will be glad to answer any questions you may have.