Introduction

Once a tray jam is detected, the tray former stops and an alarm appears on the HMI. Follow this procedure to clear a tray jam.

-

-

Press an E-STOP to remove power and air.

-

-

-

Follow lock-out/tag-out procedures before attempting to clear a tray jam. Energized tray former parts may activate causing injury.

-

Lock-out the Control Panel disconnect switch.

-

Lock-out the air regulator assembly (FRC).

-

If your tray former has a separate disconnect for the hot melt system, lock-out the switch.

-

-

-

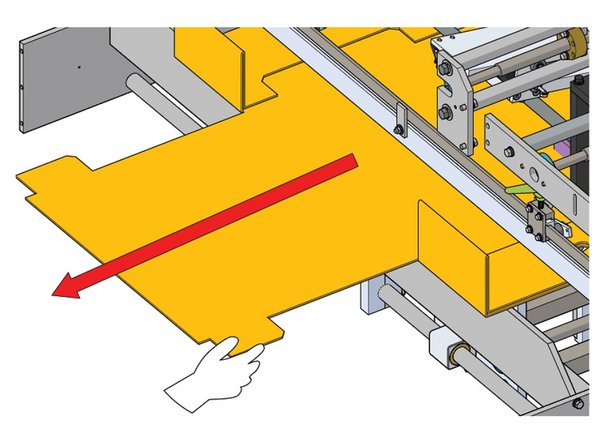

Access the area where the jam occurred.

-

Carefully remove the damaged tray. Make sure the area is clear of any corrugate pieces.

-

Close all guard doors and make sure all personnel are clear of the tray former.

-

-

-

Remove lock-outs. Turn the control panel disconnect and air shutoff valve to the On positions. If necessary, restore power to the hot melt system.

-

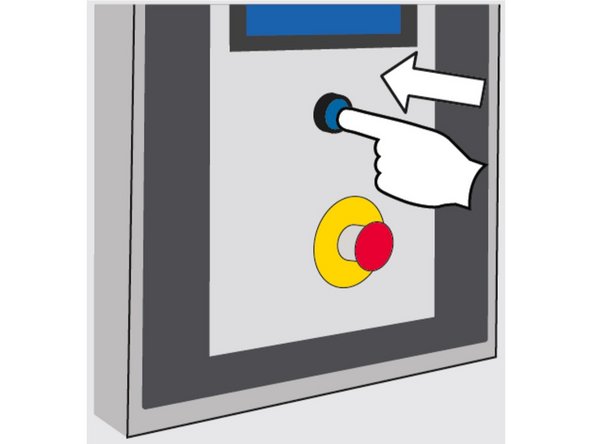

Release the E-Stop button.

-

Press the Reset button on the control panel.

-

When the tray former has finished resetting, touch the green Start button on the HMI.

Thank you for contacting us. For us to better assist you, please reach out to our technical support by phone at 1.888.565.3219 or 604.930.9300 or by email at Wexxar.Service@promachbuilt.com or Wexxar.Parts@promachbuilt.com along with your machine model and serial number. One of our tech support reps will be glad to answer any questions you may have.

When the tray former has finished resetting, touch the green Start button on the HMI.

Thank you for contacting us. For us to better assist you, please reach out to our technical support by phone at 1.888.565.3219 or 604.930.9300 or by email at Wexxar.Service@promachbuilt.com or Wexxar.Parts@promachbuilt.com along with your machine model and serial number. One of our tech support reps will be glad to answer any questions you may have.