-

-

The machine should be installed on a level surface to prevent frame stress and ensure optimal performance. It comes with adjustable leg-height and leveling pads, with optional adjustable casters. After setting the infeed/outfeed height, use a spirit level along and across the frame to level the machine.

-

-

-

The BEL 451 uses single-phase 120 VAC / 60 Hz electrics built to NEMA 12 standards. It features a 1/2 HP TEFC motor drawing 8 A for the conveyor drive, and a 1/4 HP TEFC motor drawing 5 A for the vacuum fan, totaling 13 A. The machine connects to an outlet with a standard cord and 3-prong plug.

-

A minimum 14-gauge (AWG) power extension cord with a three-pin connection is required to connect the machine to the power source. A dedicated electrical circuit is necessary. Any electrical connections for installation must be performed by a qualified electrician in your jurisdiction.

-

-

-

Press Stop and turn Off the vacuum fan before performing the following steps.

-

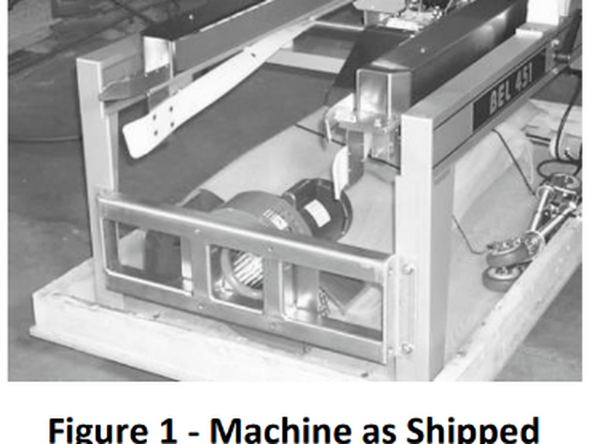

The vacuum plenum assembly is removed for shipping. Re-install it on the front of the machine as shown in Figure 1 to Figure 3 below.

-

1-Remove the plenum assembly from the shipping pallet base and install it on the front of the machine with the four 3/8” NC bolts provided. (Figure 2).

-

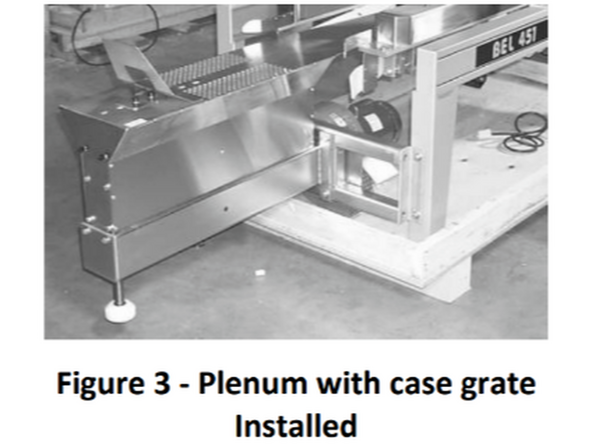

2-Adjust the height of the additional footpad under the end of the plenum to provide additional support (Figure 3).

-

A single case grate that is the top part of the vacuum plenum assembly is supplied as standard, according to the case width specification provided at the time of order. Additional case grates of different width can be supplied to match other cases, they can be interchanged as needed

-

-

-

If there are multiple case sizes with notable width differences, more than one case grate may be provided. The grate should ideally be within 1” of the case’s inside width to ensure a good vacuum effect and product support. To swap grates, loosen the thumbscrews at both ends and lift the grates straight up.

-

Almost done!

Finish Line