Introduction

To install the Wexxar BEL 290 Case Former, you will require:

· A spirit level to level the machine.

· Compressed air and electrical power supplies.

Use a forklift to remove the machine from the base. Use appropriate wood blocking (i.e.: 4 pieces of 4” x 4” x 12” timber) to avoid fork contact with protruding parts.

-

-

1. Remove the bolts that secure the BEL 290 to the shipping base.

-

2. Use a forklift to move the machine off its base, with wooden blocks between the forks and the frame.

-

3. While the machine is elevated, install the footpad extensions or castor extensions to the bottom of each leg and adjust them for the desired operating height.

-

4. Position the BEL 290 where it is to be used.

-

-

-

The hot melt system should be mounted on a freestanding table. The electrical power, pneumatic air supply, and insulated adhesive hose need to be connected.

-

Refer to the separate Hot Melt System Manual for further details on installing and setting up the hot melt tank.

-

-

-

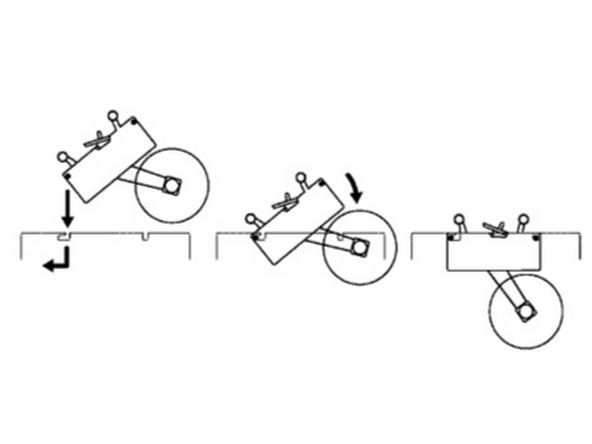

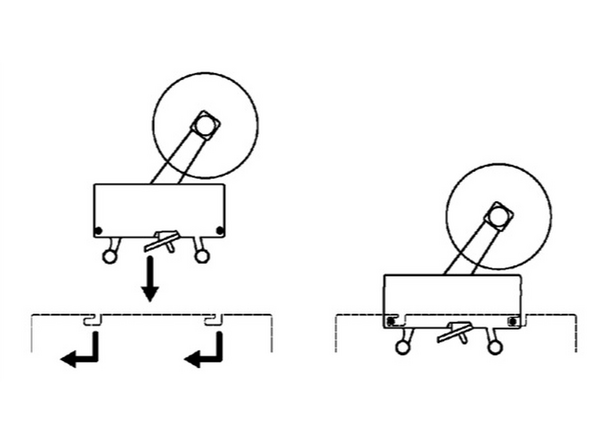

Machines are shipped with the tape heads secured in their brackets. To reinstall the tape heads, lower them into the brackets to align the pins on their sides with the slots in the brackets. Follow these steps:

-

Bottom Tape Head Place the tape head’s rear pins into the slots of the bracket. Then, slide to lock. Pivot down the free end so that the pins rest in the aligned slots.

-

Top Tape Head Place all of the tape head’s four pins in the slots of the bracket. Slide to secure, then lock them in place with the thumb screws.

-

Please consult the tape head manual for instructions on the mounting of tape rolls and the proper threading of tape through the applicator head.

-

-

-

Service connections (electrical and pneumatic) should ONLY be undertaken by qualified personnel. Observe proper lock-out procedures and recommended sequence to avoid personal injury or damage to the machine.

-

Electrical Power The BEL 290 is equipped with single phase, 120-600V electronics and manufactured to NEMA 12 specifications. A 1/2 horsepower TEFC motor powers the uni-drive system.

-

A minimum AWG 14 gauge wire must be used to connect the machine to the power source. The machine must be grounded.

-

Any electrical connections that are needed to install the machine must be handled by a qualified electrician in your jurisdiction.

-

-

-

Compressed Air The BEL 290 requires an air supply, which must be clean and dry, with a PSI between 80 and 120 and an optimal pressure of 90 PSI. The volume of air required for the BEL 290 (main regulator) is rated at 0.16 C.F./cycle at 90 PSI (6 Bar)70 PSI. (4.8 Bar).

-

The incoming air supply line must be of sufficient diameter to provide an adequate amount of air without pressure drops when the machine is cycling.

-

A 1/2” air line size is recommended.

-

One of the most common causes of inconsistent machine performance is inadequate air supply. Meeting machine air requirements is important to assure satisfactory operation.

-

The BEL 290 is equipped with an air filter/regulator and second coalescing filter which should be checked periodically to ensure that the air pressure is regulated to the proper setting, and that the filters are not contaminated.

-