-

-

Remove the lag screws that secure each leg to the pallet base. Lift the machine off the shipping pallet and move it to the work location. Always use wooden dunnage blocks under the lower frame when using a forklift to move the machine from the shipping pallet or to re-position it on the floor.

-

-

-

The base of the frame should be made level to ensure personnel safety, provide optimum performance, and avoid frame stress.

-

-

-

The standard BEL 270 is made to NEMA 12 specifications and requires a single-phase 240V AC power supply for both the main machine operation and the hot melt system. A 1/2 HP TEFC motor (rated 3.7A @ 230 V.) powers the conveyor drive. The control voltage is 24 VDC

-

A dedicated electrical circuit is recommended for this machine. If any electrical connections are required to install this machine, they MUST be handled by an electrician qualified in your area.

-

-

-

The BEL 270 requires a clean, dry air supply with a constant pressure of 80 PSI. The volume of air required for the BEL 270 is 0.2 C.F./cycle at 80 PSI, (6 Bar). The incoming air supply line must be at least a ½” ID to provide an adequate amount of air without pressure drops when the machine is cycling

-

One of the most common causes of inconsistent machine performance is inadequate air supply. Therefore, the foregoing requirements must be carefully observed to assure satisfactory operation

-

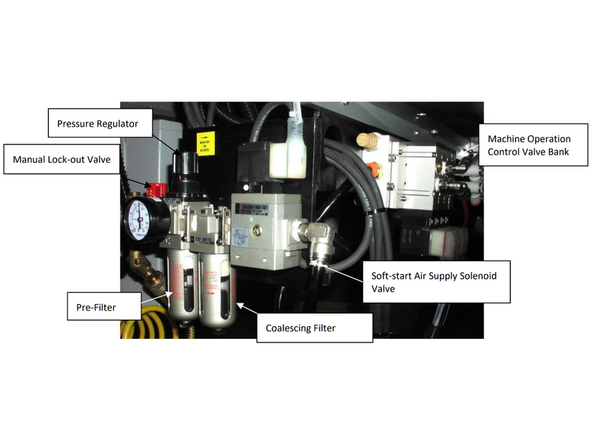

The BEL 270 is equipped with a combined inlet filter / regulator and second coalescing filter. It also has an electrical air supply valve controlled by the ON/OFF switch circuit. Switching OFF the machine will exhaust compressed air in the machine circuit.

-

WARNING When the machine is connected to an air supply and first turned ON, the Snap Folders will cycle once. Ensure that all personnel are clear of the machine when it is starting

-

Almost done!

Finish Line