-

-

The BEL 505 G4 should not be stored or transported in extreme temperatures. Transport and store the machine in a covered environment not directly exposed to the natural elements such as rain, snow, or wind. When transporting the machine, it should be safely secured to prevent shifting within its packaging.

-

-

-

Unpack the machine and remove any packing material from the interior. Remove from underneath, any support used to protect components during shipping.

-

Install the legs at each of the three positions on the machine frame. If the 505 G4 is to be mounted on [and supported from] the case sealer, refer to the instructions included with the mounting kit.

-

-

-

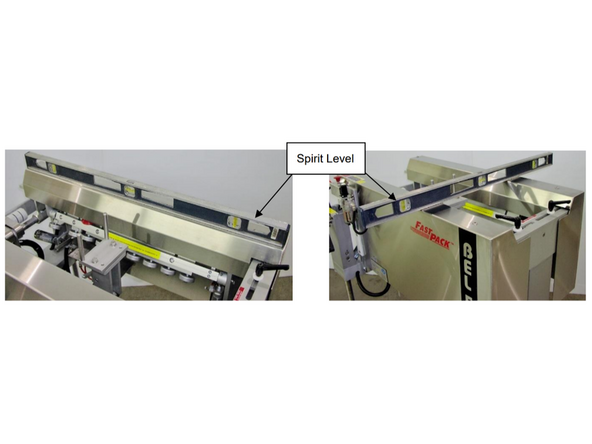

The base of the frame should be made level to ensure personnel safety, provide optimum performance, and avoid frame stress

-

-

-

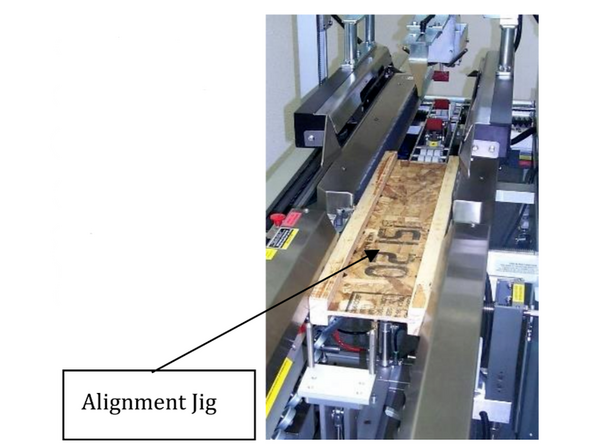

The machine should be securely mounted to adjoining equipment to prevent the machine moving as it operates. If being directly connected to a BEL case sealer, it is important that the centers of both machines be in line for ease of case transfer between machines

-

When a BEL 505 G4 is provided together with a BEL sealer, a jig is provided to further assist in aligning the machines. The BEL 505 G4 should be level with, or slightly higher than, the case sealer conveyor.

-

-

-

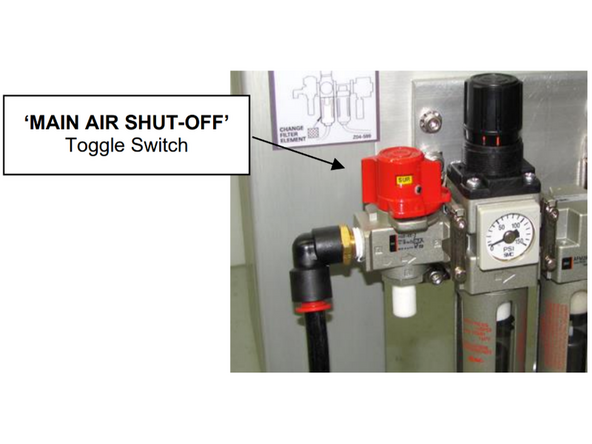

Ensure that the red ‘EMERGENCY STOP’ button is pushed down (OFF) and that the red main air shutoff valve is in the ‘off’ position before connecting an air supply to the machine.

-

The air may come from either a separate source or by tapping off the supply of an adjoining case sealer, but it must be clean factory air. Air pressure should be set to 80 psi. for most applications with a minimum setting of 65 psi and a maximum of 100 psi.

-

The machine is equipped with a lock-out-tag-out-equipped ‘MAIN AIR SHUTOFF’ valve on the Machine’s FRF unit.

-

-

-

The BEL 505 G4 is equipped with single-phase 115 VAC / 60 HZ electrics manufactured to NEMA 12 specifications.

-

The machine is connected to an electrical outlet with a conventional cord and 3- prong plug. If required, a 14-gauge (AWG) power extension cord with standard three-pin connection must be used to connect the machine to the power source.

-

A dedicated electrical circuit is recommended for this machine. If any electrical connections are needed to install the machine, these must be handled by an electrician qualified in your jurisdiction.

-

Switch the machine OFF by pushing down the red ‘EMERGENCY STOP’ button before making any changes or adjustments.

-

Almost done!

Finish Line