-

-

1-Remove all packing materials and supports from the interior and from underneath your machine

-

2-For all three machine frame legs, slide a leg extension through each hole on the frame. Tighten the nut and washer on either side of the frame to secure each leg extension.

-

-

-

Level machine before operating. Adjust all three leg extensions with pads or casters, as needed

-

If your machine is not level, using the width adjustment screw can cause frame stress and changes to alignment.

-

-

-

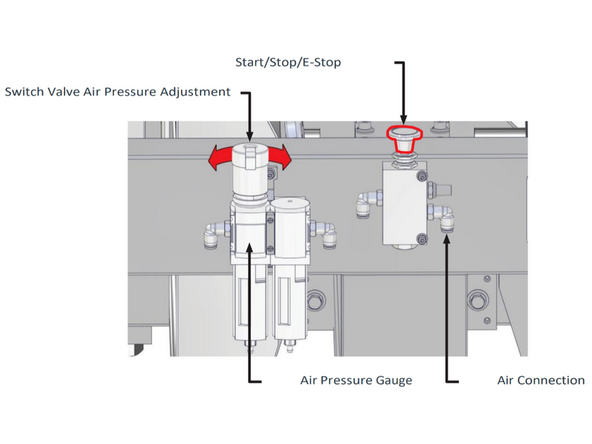

-Before operating your machine, read and understand the Safety section on page 7. -Turn OFF the manual Start/Stop/E-Stop Switch Valve and lockout the Filter Regulator before making any adjustments.

-

-The supply must be clean factory air. Air pressure should be set to 80 PSI for most applications with a minimum setting of 65 PSI and a maximum of 100 PSI.

-

-The air may come from either a separate source or by tapping off the supply of an adjoining case sealer. Your machine comes with a push-to-connect fitting for ¼” O.D. air tubing. The supply must be clean factory air without excessive moisture

-

Almost done!

Finish Line