-

-

1-Remove all packing materials and supports from the interior and from underneath your machine.

-

2-For all five machine frame legs, slide a leg extension through the hole of each frame leg. Tighten the nut and washer on either side of the frame to secure each leg extension.

-

If transporting or storing your machine, see Safety and Machine Care Sections on User Manual.

-

-

-

Level machine before operating. Adjust all five leg extensions with pads or casters, as needed.

-

If your machine is not level, using the width adjustment screw can cause frame stress and changes to alignment.

-

-

-

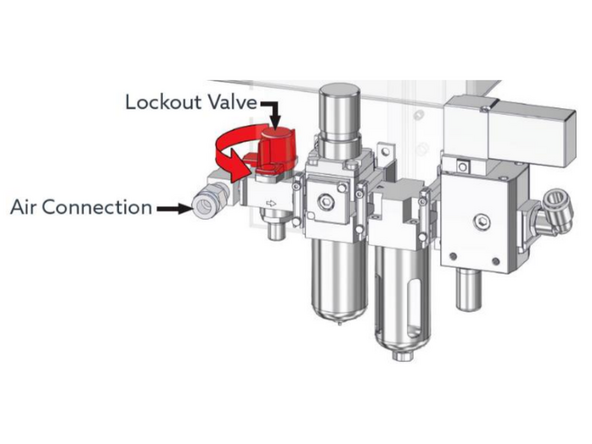

Turn OFF the manual air supply lockout valve before connecting an air supply to your machine.

-

The supply must be clean factory air. Air pressure should be set to 80 PSI for most applications with a minimum setting of 65 PSI and a maximum of 100 PSI.

-

-

-

Only a qualified electrician should handle any new electrical connections needed for your machine

-

A dedicated circuit is recommended for your machine.

-

See “Electrical Specifications”

-

If required, only use a three-pin, minimum 14 gauge (AWG) power extension cord to connect your machine to a power source

-

The equipment operates on 120 VAC with a full-load amperage of 10 A, and is designed for 1-phase, 60 Hz power. It meets NEMA 12 standards and requires a 3-prong, 14-gauge (AWG) power cord.

-

The control system features a SIEMENS LOGO logic controller with non-contact photo-sensors and solenoid valves running at 24 VDC. The conveyor drive is powered by a 1/2 HP TEFC motor drawing 8 amps.

-

Almost done!

Finish Line