-

-

The BEL 5252U should not be stored or transported in extreme temperatures. Transport and store in a covered environment not directly exposed to the natural elements, such as rain, snow, or wind. When transporting the machine, it should be safely secured to prevent movement.

-

-

-

Unpack the machine and remove any packing material from the interior or any support used underneath to protect components during shipping

-

Install the threaded leg extensions with either pads or optional casters at each of the five positions on the machine frame with one nut and washer for each leg underneath the frame and another nut and washer on the inside of the frame

-

Remove the forklift lifting bars from the machine legs before putting the machine into operation.

-

-

-

The base of the frame should be made level to ensure personnel safety, provide optimum performance, and avoid frame stress.

-

All 5 leg extensions with pads or casters must be made level to each other before using the width adjustment screw to avoid frame stress and changes to alignment.

-

-

-

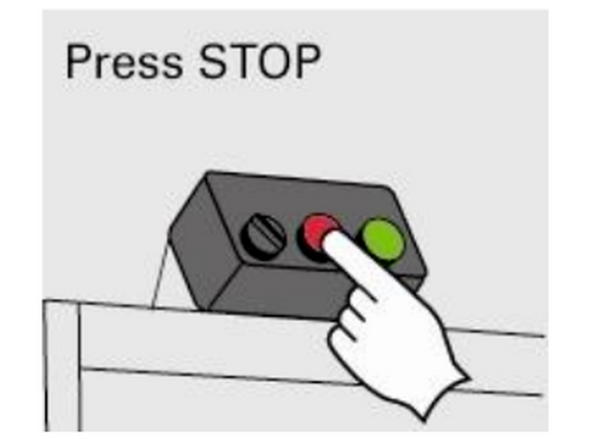

Press Stop before connecting an air supply to the machine

-

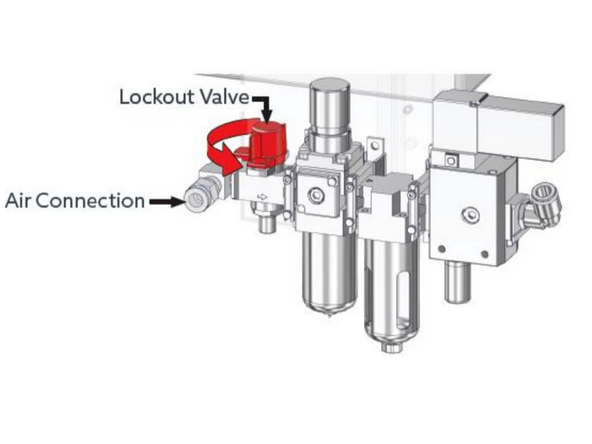

The supply must be clean factory air. Air pressure should be set to 80 PSI for most applications with a minimum setting of 65 PSI and a maximum of 100 PSI.

-

-

-

The BEL 5252Uis equipped with single-phase 120 VAC / 60 HZ electrics manufactured to NEMA 12 specifications. The unit uses a Siemens LOGO programmable control and SMC brand solenoid air valves.

-

The sealer conveyor drive system is powered by a 1/2 horsepower TEFC motor that draws eight amps. The machine is connected to an electrical outlet with a conventional cord and 3-prong plug. If required, a 14- gauge (AWG) power extension cord with standard three-pin connection must be used to connect the machine to the power source.

-

A dedicated electrical circuit is recommended for this machine. If any electrical connections are needed to install the machine, these must be handled by an electrician qualified in your jurisdiction

-

Almost done!

Finish Line