Introduction

To install the DEKKA 500 Case Former, you will require:

· A spirit level to level the machine.

· Compressed air and electrical power supplies.

-

-

Use a forklift to remove the machine from the base. Use appropriate wood blocking (i.e.: 4 pieces of 4” x 4” x 12” timber) to avoid fork contact with protruding parts.

-

1. Remove the bolts that secure the DEKKA 500 to the shipping base.

-

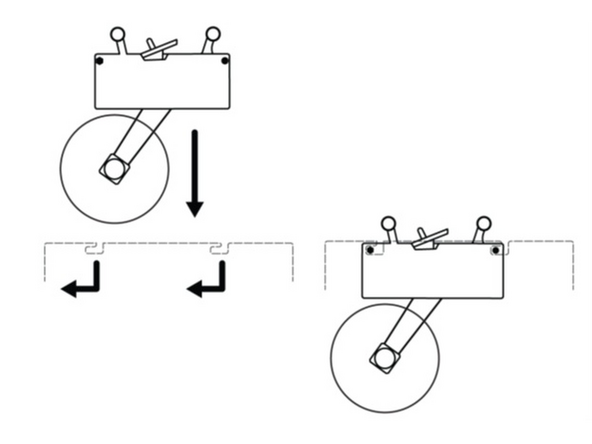

2. Use a forklift to move the machine off its base, with wooden blocks between the forks and the frame.

-

3. While the machine is elevated, install the footpad extensions or castor extensions to the bottom of each leg and adjust them for the desired operating height.

-

4. Position the DEKKA 500 where it is to be used.

-

-

-

The machine should be installed in a level position to avoid frame stress and ensure optimum performance. An adjustable height footpad kit is included as standard equipment and can be used to level the machine on an uneven floor.

-

We recommend that you anchor the machine to prevent unwanted vibrations or movement during normal operation.

-

-

-

Machines are shipped with the tape head secured in its bracket. To reinstall the tape head, lower them into the brackets to align the pins on their sides with the slots in the bracket.

-

Please consult the tape head manual for instructions on the mounting of tape rolls and the proper threading of tape through the applicator head.

-

-

-

Electric A minimum AWG 14 gauge power extension cord with standard three-pin connection must be used to connect the machine to a power source (120 VAC, 60 Hz, 8 Amps, and 1 Ph).

-

If any electrical connections are needed to install the machine, they must be handled by a qualified electrician in your jurisdiction.

-

-

-

Compressed Air The DEKKA 500 requires an air supply, which must be clean and dry, with a PSI between 80 and 120 and an optimal pressure of 90 PSI. The volume of air required for the DEKKA 500 (main regulator) is rated at 1.0 C.F./cycle at 90 PSI. (6.2 Bar).

-

The incoming air supply line must be of sufficient diameter to provide an adequate amount of air without pressure drops when the machine is cycling.

-

A 1/2” to 3/4” air line size is recommended.

-

NOTE: A common cause of inconsistent machine performance is inadequate air supply. Therefore, meeting machine air requirements is important to assure satisfactory operation.

-

The DEKKA 500 is equipped with an air filter/regulator/lubricator and second coalescing filter which should be checked periodically to ensure that the air pressure is regulated to the proper setting, and that the filters are not contaminated.

-