-

-

Whether the machine is on standard footpads or optional casters it is always good practice to level the machine on pads with a spirit level or ensure equal height adjustment of the casters to minimize stress on the machine frame and ensure adjustments move freely.

-

-

-

Electrical System

-

The BEL 185 is single-phase 110-120 VAC and manufactured to NEMA 12 specifications. The top and bottom drive system is powered by upper and lower gear-motors that together draw 5.5 amps. If required, a minimum 14-gauge (AWG) power extension cord with a standard three-pin connection must be used to connect the machine to the power source.

-

Compressed Air

-

Ensure that the red manual air supply lock-out valve is in the OFF position before connecting an air supply to the machine

-

The BEL 185 requires an air supply that must be clean and dry and at an optimal pressure of 80 PSI. The volume of air required is 0.02 CF/cycle at 80 PSI (6 Bar). The air supply line must be of sufficient diameter to provide an adequate amount of air without pressure drops when the machine is cycling. A ½” air-line size is recommended.

-

One of the most common causes of inconsistent machine performance is inadequate air supply. Therefore, meeting machine air requirements is important to assure satisfactory operation. The BEL 185 is equipped with both solenoid and manual compressed air shut-off/dump valves, and a Filter/Regulator/Filter (FRF).

-

-

-

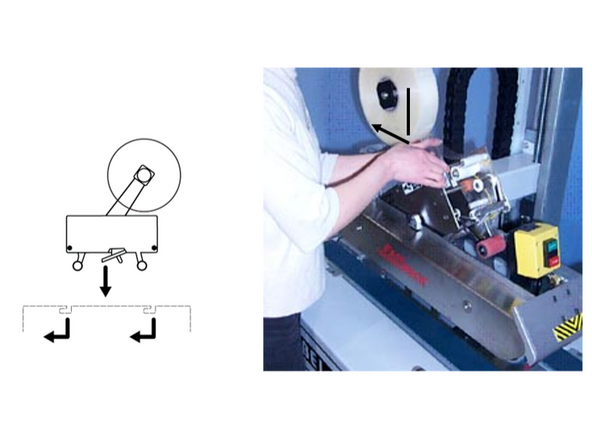

Tape dispensing heads are mounted with pins on their sides that fit into corresponding slots in the upper and lower tape-head mounting positions.

-

Bottom Tape Head

-

1-Raise the top conveyor and tape head holder to its highest position by turning the Height Adjustment Handle.

-

2-Fit the bottom head down into the vertical slots of the bottom holder. The head is held in place by its own weight.

-

-

-

1-Lower the top conveyor and tape head holder to its lowest position by turning the Height Adjustment Handle.

-

2-Lower the tape head into the holder while aligning the tape head pins to the slots. Push to slide the tape head toward the rear of machine to lock it in place.

-

3-Tighten the head-locking screw.

-

Please consult the tape head manual for instructions on the mounting of tape rolls and the proper threading of tape through the applicator head.

-

Almost done!

Finish Line