Introduction

Overview

The servo belt drive moves tray blanks from the hopper through glue application to the compression section of the machine. The servo belt drive is controlled for precise speed and positioning. To ensure the drive belt maintains its position, the coupling that connects the servo motor to the drive belt should be kept tight. Ideal tension is 87 in/lbs.

The coupling should be tightened at the one year mark, and then once a year after that.

Parts

No parts specified.

-

-

Using a ½” wrench, remove the two bolts that secure the lug guard and pull the lug guard off the machine.

-

-

-

On the gear box, using a 5mm Allen key, remove the set screw.

-

Position a light for a clear view of the access hole.

-

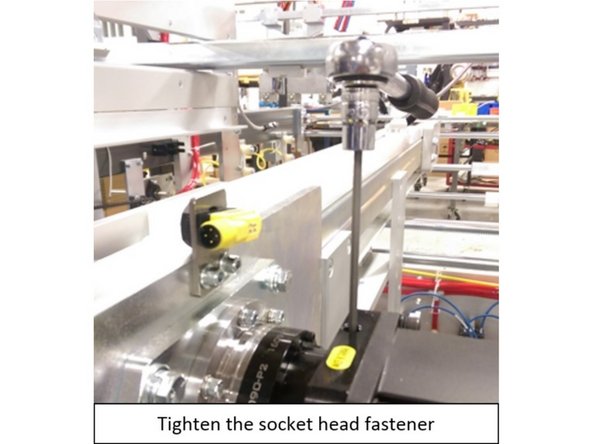

Slowly push the feed belt forward until the socket head fastener on the coupling lines up with the hole.

-

-

-

Using a 4mm Allen key, tighten the socket head fastener to 87 in/lbs.

-

Tighten the set screw.

-

Replace the lug guard.

-